Product Description

Polysulfone (PSU) is a rigid high-strength semi-tough transparent plastic that offers higher heat resistance and better hydrolytic stability than polycarbonate (PC). It retains its good mechanical properties when exposed to steam and other sterilization techniques.

Polysulfone ATD

The PSU ATD accessory is produced under the international standard design.

8040:

Size Information

Name

Code

Used

Material

O.D.

I.D.

Height

ATD

8040

Food and beverage, biological medicine, medical dialysis

PSU

200MM

38.22MM

24.6MM

ATD

4040

Food and beverage, biological ; medicine, medical dialysis

PSU

98MM

21.6MM

29.7MM

ATD

2540

Food and beverage, biological ; medicine, medical dialysis

PSU

60.5MM

19.3MM

32.7MM

Polysulfone (PSU) belong to a family of sulfur-containing thermoplastics, closely related to polyethersulfone (PES). Generally, this amber colored semi-transparent polysulfone is a high cost, rigid, material with low moisture absorption. Reinforcement improves toughness and further enhances dimensional stability, but turns materials opaque. In addition, polysulfones are characterized by high strength, very high surface-temperature limits, low creep, good electrical characteristics, transparency, self-extinguishing ability, and resistance to greases, many solvents, and chemicals, relative to polycarbonates.Polysufones may be processed by extrusion, injection molding, and blow molding. Polysulfone can be used as an alternative to polycarbonate or acrylic for applications requiring high temperature performance or exposure to hot water and steam.

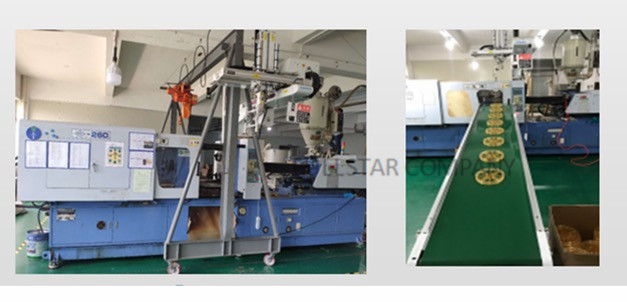

Company Introduction

The company professional manufacturer for the multi-purpose accessories of membrane filter such as polysulfone permeate tubes, polysulfone ATD, polysulfone connector, ABS tubes, ABS ATD in China. Supreme materials, complete set of advanced equipment, skilled workers, special leading formula technique and 3 inspection lines ensure Company provide a full range of professional products in high and stable quality to the customers.

Company advantages features of our products are with high intensity, high glossy, smooth inner wall, and accuracy because the application of the new extrusion process and stress elimination technology. Our products have obtained FDA certificate. The company can also provide OEM services under customers' requirements. Now, the products have been widely used in the fields of filtration and separation of membrane cores in beverage, food, pharmaceutical, chemical, laboratory, environmental engineering and bioengineering industries.

Workshop

sale@banmoon.com

sale@banmoon.com

IPv6 network supported

IPv6 network supported